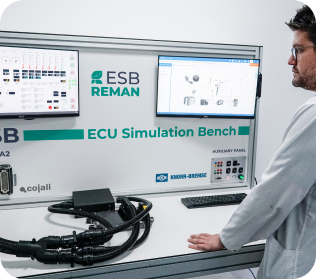

ESB REMAN uses Jaltest ESB technology, the ECU simulation bench developed by Cojali to diagnose, recondition and test the operation of the most important electronic control units in commercial vehicles.

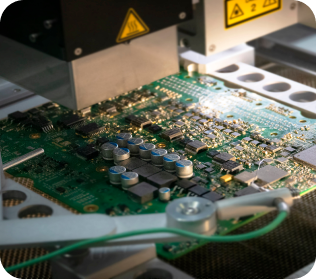

Reconditioning is a thorough process in which damaged or worn ECU components are checked and replaced, while retaining the same specifications as the new product.

Receipt and initial diagnostics

Reconditioning and testing

Assembly and shipping